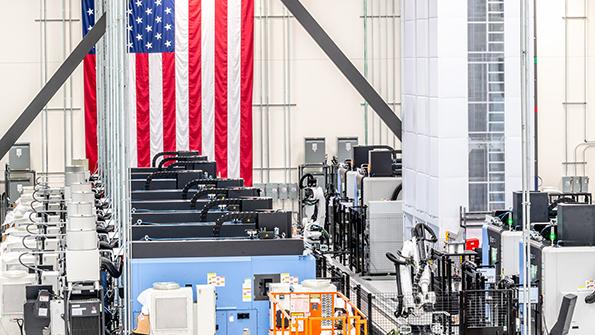

The Sept 2-15 issue of Aviation Week & Space Technology includes two articles discussing ongoing efforts to automate aerospace manufacturing. The first, titled “Automating Aerospace” by Garrett Reim outlines the efforts of a company called Divergent Technologies. Divergent is “pioneering the development of a fixtureless assembly cell, a sort of mechanical maypole with 22 robotic arms encircling one central arm. The arms pick up 3D-printed parts and hold the metal pieces together to be glued into a larger structure such as a car chassis or an attritable drone.” The company has already demonstrated the ability to assemble a Sparrowhawk UAV (a mini-UAV designed to be launched from the MQ-6 Reaper) in just six minutes. A process that would take hours via traditional means. Divergent Technologies has caught the attention of the Pentagon who believes their technology will be useful to quickly mass produce everything from drones to missiles and spacecraft.

In a second article entitled Is the Future Robotic, Garrent Reim outlines the efforts of a cohort of advanced manufacturing companies that are trying to solve the aerospace industry’s skilled labor shortage through the use of AI. The cohort is mostly focused on using AI to analyze computer drawings and manufacture unique parts normally done by highly skilled, and increasingly rare, human machinists. These machinist’s produce parts for everything from aircraft parts, to specific fine tolerance parts for spacecraft. Automating the machining process is the most practical way to save time and money during manufacturing while also making up for extreme shortage of skilled human labor needed to produce such parts.

While it is easy to argue that the automation of aerospace manufacturing is smart, and indeed necessary to quickly mass produce critical defense systems and parts needed for those systems, this effort must have cybersecurity baked in from the start. A highly automated manufacturing process gives an adversary the opportunity to hack into your system and make subtle changes to processes that could have dire effects on a system once it is put into use. For example if a small sat constellation is produced in an automated factory an adversary could gain access to robotic arm programming and change it to insert a component backwards or place sealant improperly or any other number of subtle variations that could be difficult for a human inspector to catch, but would cause the system to fail either on orbit, or during preflight testing.

Works Cited

Reim, Garrett (2024) Automating Aerospace (p48) & Is the Future Robotic (p53) Aviation Week & Space Technology (Sept 2-15 2024). https://aviationweek.com/aerospace/manufacturing-supply-chain/aerospace-manufacturings-future-robotic